Testimonials & Articles

![]() Extract of

an article by Paul Goldie in the Mining Chronicle Vol 2 number 12 Dec

1997, page 46

Extract of

an article by Paul Goldie in the Mining Chronicle Vol 2 number 12 Dec

1997, page 46

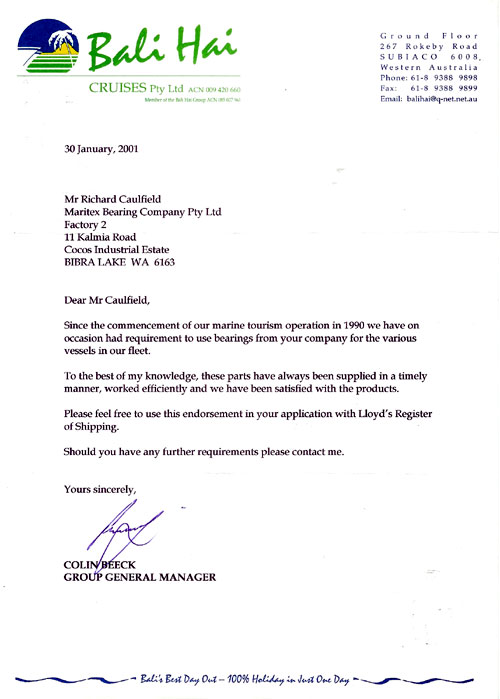

Problem-solving material for bearings

BY PAUL GOLDIE A new material, which will solve many of the plain bearing problems encountered with conventional materials, is being manufactured by the Maritex Bearing Company.Richard Caulfield of Maritex said that a lot of the plastic types of materials, when used as plain bearings and subjected to heat or pressure or both, tend to deteriate in the sense that they may creep or deform and in some cases, melt. “Our material is a true composite made up of two compounds, neither of which will be satisfactory on its own. They are combined to provide the desired result and then some highly secret materials are added and a special process is applied. It is a complex material, both in method of manufacture and in ingredients.” To illustrate the material’s ability to solve difficult problems, Mr. Caulfield recounted a successful application in the mining industry: “Hamersley Iron had used bearings which contained asbestos in the direct contact heater extraction pumps at the power station in Dampier. The pumps are critical because failure can affect generating capacity.

“To their credit Hamersley withdrew the bearings many years ago as part of a policy to to remove all asbestos from company sites, even though they worked very well. However, they then had the greatest difficulty in finding a replacement material. The situation had become so desperate that they were even considering re-designing and re-manufacturing the pumps to suit available materials. The operating environment for the bearings is between 90ºC and 120ºC but the resin we use in our product is capable of withstanding 200ºC and it will hold reasonably good mechanical integrity at that temperature. Most thermoplastics will, if they haven’t already melted, have lost their strength and become plastic and soft. Our product also has very low thermal and moisture swelling which is, of course, extremely important in such applications. Materials such as nylon tend to swell in water; I believe around 6 percent, but our material has been tested to consistently swell less than 1 percent.

“Hamersley Iron contacted us after receiving a recommendation and, after some initial testing and modification, our bearings outperformed all of the materials trialled, including the original asbestos bearings

![]() Article by Paul Goldie in the Mining Chronicle Vol

3 number 2 March 1998, page 22

Article by Paul Goldie in the Mining Chronicle Vol

3 number 2 March 1998, page 22

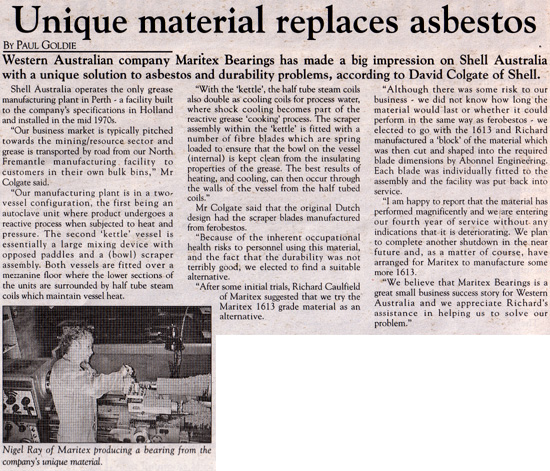

![]() Testimonial

from Shep's Engine Reconditioning Specialists

Testimonial

from Shep's Engine Reconditioning Specialists

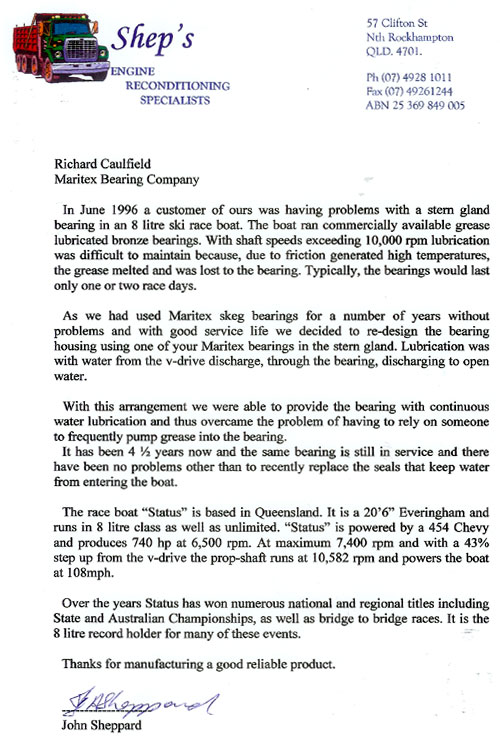

![]() Testimonial

from Steelform Hydraulics

Testimonial

from Steelform Hydraulics

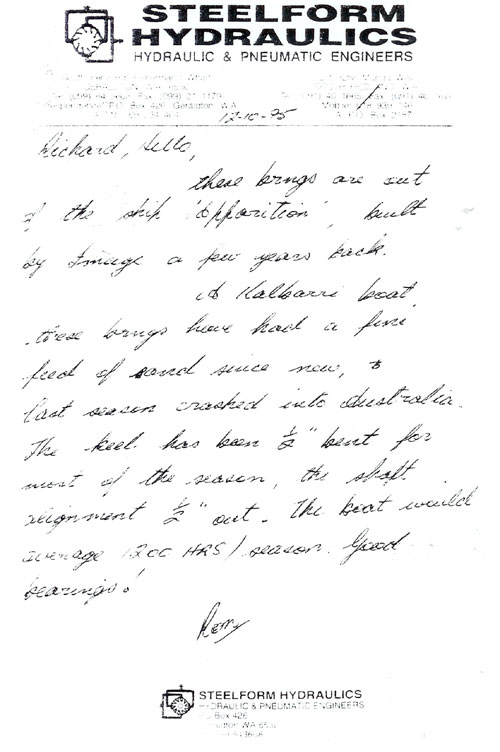

![]() Testimonial

from Bali Hai

Testimonial

from Bali Hai